E-mail : huayun@bdhyjx.com

Surface treatment after repairing the endless conveyor belt: polish the repaired area and the range of 10 cm around it, and clean the debris. According to the actual damage, arrange the steps at 60 to 90 degrees, with leaking glue points on the surface. Use a special cleaning agent to clean the surface after bonding and sealing;

Repairing method with glue: Mix the resin and curing agent according to the proportion and mix them evenly for two minutes, and apply to the crack. The whole process should be controlled within ten minutes. The mixed repair agent will self-fluidize at the damaged place. The curing time is based on the working temperature on site. Depends, the higher the curing time, the shorter the curing time. At this time, infrared heat lamp can be used to increase the temperature;

Cold vulcanization adhesive strip repair method: suitable for the repair of rubber belts with high requirements for tensile resistance, wear resistance, heat resistance, flame resistance, and radiation resistance, just apply cold vulcanization adhesive on the bonding surface, the advantage is tensile resistance High strength, fast repair, simple operation, time-saving, very suitable for long-distance belt conveyor line body scratches, edge wear, local rubber layer damage, belt cold bonding, and other working conditions, which can avoid longitudinally torn belts Remove and use ordinary hot vulcanization joint method;

When repairing, first polish and mark the breach, and then polish the part until the surface shows a certain curvature and no protrusions. Wash the polished surface and apply the adhesive. Leave it to dry until it is slightly sticky. If the rubber is damaged If it is too large, the patch can be filled and pasted first, and the air should be avoided as much as possible, and then use a pressing wheel to roll and compact from the inside to the outside, and discharge the air bubbles;

Conventional joints are lapped by common metal belt buckles, which are most suitable for the temporary repair of longitudinal tears of ordinary conveyor belts, and transverse connections. The conveyor belt buckles are made of high-strength alloy plates, which are resistant to salt and alkali, moisture, and oxidation. The front steel nails have strong penetrating power and short operating hours, which can meet the needs of five to fifteen mm thick belt joints, and make up for the time-consuming and laborious vulcanization joints. However, the belt buckle has a short service life and generally has a tight downtime. In case of repair with cold vulcanization repair strip;

The comprehensive repair method can be used to repair the belt scratches within the specified range. The resource investment is low, and the operator can complete it independently. The repair of the belt longitudinal crack within each meter only takes two hours. If the scratch is long, the belt buckle can be used together. This method does not require professional bonding engineers, and at the same time, it avoids the up and down transportation of the vulcanizer, reduces labor intensity, and improves efficiency. At the same time, the surface of the belt body after the repair is smooth, without protrusions, and will not be scratched by facilities, and has good wear resistance. The characteristics are completely equivalent to the life cycle of newly purchased rubber conveyor belts.

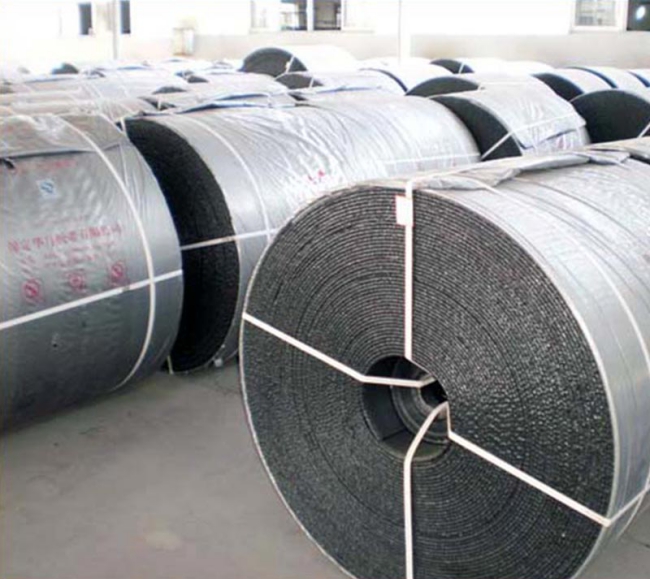

The above information is provided by the fabric conveyor belt factory.

Copyright © Baoding Huayun Conveyor Machinery Co., Ltd. All Rights Reserved | Sitemap |