E-mail : huayun@bdhyjx.com

Three sets of steel wire cord belt samples are selected to analyze the relationship between the thickness of the steel wire belt covering rubber and the damage energy of the belt body. From the test results, it can be seen that the thickness of the steel wire belt covering rubber is the main factor affecting its impact strength. Timing, as the thickness of the covering rubber increases, the energy required for the first damage and first penetration of the belt increases significantly, but when it reaches a certain thickness, the increasing trend slows down or even decreases. It can be seen that the impact resistance of the steel cord conveyor belt is the best impact resistance can be obtained within the thickness of the cover rubber. The best impact resistance can be obtained when the thickness of the cover rubber on the steel wire belt of the specification ST800 is 8 mm. When the steel cord belt of the specification ST1250 and ST2500 is selected, the upper The best impact strength can be obtained when the cover rubber is 10 mm.

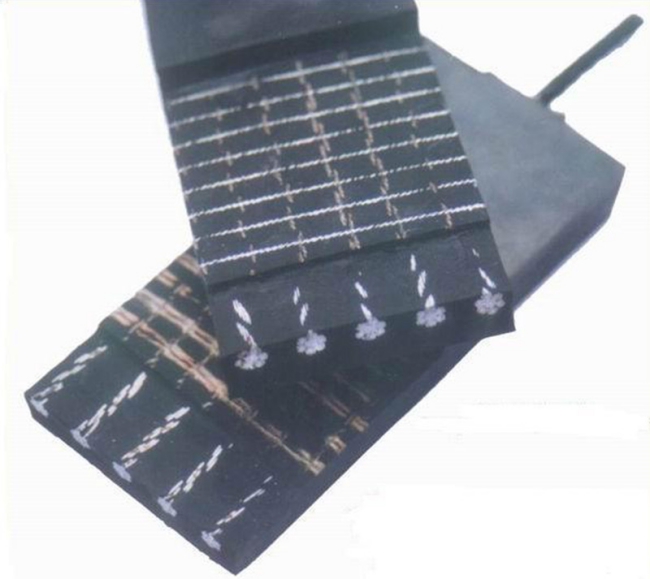

The influence of the transverse reinforcement on the impact resistance of the steel cord conveyor belt: three sets of sample belts are selected to analyze the relationship between the transverse reinforcement and the damage energy of the steel cord conveyor belt. From the data of the test results, it can be seen that when the rated strength remains unchanged, the single weft direction Reinforcement can improve the impact resistance of the belt body, and the double weft reinforcement can further improve its impact resistance. In addition, as the rated strength of the wire cord belt increases, the effect of the transverse reinforcement on improving the impact resistance will be weakened.

According to the test results of the tear-resistant rubber conveyor belt with a cover rubber thickness of 10mm and a rated strength of ST1250, it is shown that the physical properties of the steel wire cord conveyor belt cover rubber have a certain impact on its impact strength, especially the penetration energy ratio of the scratch-resistant cover rubber The other two cover rubbers have a 30% higher strength, and their tensile strength, elongation strength, and hardness are much higher than the other two cover rubbers. Therefore, they have higher initial damage and first penetration strength, so users can choose according to different The impact characteristics are required to select different covering rubber surfaces for steel cord belts.

According to the above analysis, the final conclusion can be summarized as follows: the external impact resistance of the steel cord conveyor belt is basically linear with the energy, the thickness of the cover rubber is the main factor affecting the impact strength of the belt, and the double weft is better than the single weft. The reinforcement can further improve the impact resistance of the steel wire cord conveyor belt, and at the same time, its impact resistance will increase with the improvement of the physical properties of the covering rubber.

The above information is provided by the fabric conveyor belt factory.

Copyright © Baoding Huayun Conveyor Machinery Co., Ltd. All Rights Reserved | Sitemap |