E-mail : huayun@bdhyjx.com

The belt roller is an important part of the belt conveyor. It has many types and large quantities, accounting for about 35% of the total parts of the conveyor equipment and can withstand more than 70% of the transportation resistance. During the use of the belt conveyor machinery, the industry Frequently, the rubber conveyor belt is cut by the gap between the ends of the friction roller, and the parts of the rollers are damaged due to excessive force on the inclined vertical rollers on both sides. This causes the expensive parts of the endless conveyor belt to wear quickly and use. The cycle is shortened, which not only affects the normal use of belt conveyor equipment but also causes excessive economic losses for enterprise users under working conditions.

Among the products currently used in the industry, in order to avoid the phenomenon of jamming caused by the movement interference between the rollers during the conveying process, the ordinary roller group manufacturers often have a certain gap between the left, middle and right three-roller accessories. In this way, when the conveyor belt is running, due to the weight of the material carried by the upper part, it will be pressed down, and a part of the rubber belt will fall into the smaller gap of the idler. As the conveyor runs, the trough-shaped idler set will The conveyor belt produces a certain cutting force, which will seriously affect the normal operation and service life of the belt body.

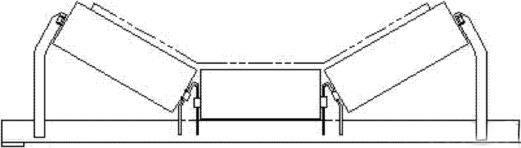

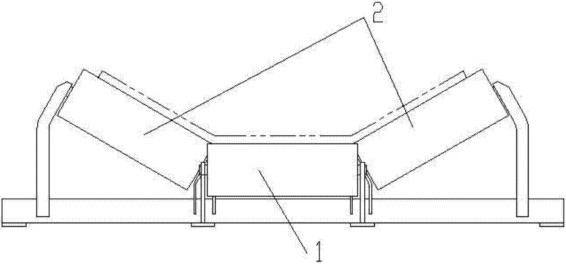

The fabric conveyor belt factory changes and optimizes the structure of the roller accessories. After accurate calculation by digital simulation technology, the middle roller moves a certain distance forward or back to keep it away from the left and right stainless steel rollers. The middle roller is arranged horizontally on one side of the axis of the left and right idler rollers and is arranged in front and back. The left and right rollers form a certain angle with them, and the size of the middle roller is increased so that its end faces exceed the left and right The two side positions of the rollers, so that the improved conveyor roller set has no gap between the rollers in the horizontal direction, and there is no cross in the vertical direction of the conveying, so when the roller is running, nylon transportation belts and other products will no longer be caught by the gap between the idlers and be damaged due to cutting. After the adoption of this idler structure, due to the increased area of the lower part of the industrial conveyor belt, it will greatly reduce the left and right sides. The lateral pressure of the vertical rollers on both sides prolongs the use time of the conveyor accessories.

The more intuitive and beneficial effects that users can feel after selecting the trough-shaped roller set accessories equipped with the above technology are mainly reflected in: it can fundamentally solve the problem of jamming of the rubber conveyor belt, cutting off the edge, or lack of force. The uniform phenomenon greatly improves the life cycle of industrial conveyor belts, belt conveyor idlers, and the working efficiency of conveying machinery and equipment, and reduces the maintenance rate of belt conveyors.

Copyright © Baoding Huayun Conveyor Machinery Co., Ltd. All Rights Reserved | Sitemap |